Fire is a silent killer. A small flame can turn into an established fire within 30 seconds, and a two-storey building can become an inferno in four and a half minutes*. Fire regulations state that a building should be evacuated in 20 minutes or less, but when fire can take hold of a building so quickly, every minute counts.

When Crystal Palace was built in 1854, it was believed that unprocessed glass was a naturally fire-resistant material. It wasn’t until Crystal Palace burned down on November 30th 1936, that the belief was disproved and work began on developing fire-resistant glass.

At the time, Crystal Palace was a one-of-a-kind building, but with breakthroughs in the development of structural glass, modern building designs - particularly across the commercial sector – are constructed from glass, which is used as a primary building material. With that, high-performance fire-resistant glass is an essential material to meet fire regulations without compromising the design of the building.

Commercial buildings are required by law to adhere to fire regulations, and your fire officer will determine what is legally required. The type of building will help establish this with factors such as:

- What the property will be used for: offices, public space, retail, leisure or residential

- The square footage of the site and how many people will likely be on the premises at any one time

- Volume and location of electrical equipment on site

- Presence of valuable items on site

The biggest killer in fire emergencies is inhalation from smoke and toxic gases. The primary purpose of fire-resistant glass is to prevent loss of human life.

Fire-resistant glass is designed to slow down the spread of fire, and contain poisonous gas and smoke for long enough to ensure a safe evacuation of civilians and also to allow fire responders to enter the building safely to attend to the fire.

Secondary to that, fire-resistant glass helps protect valuable assets from combusting. Such as data centres and server rooms, storage rooms for valuable and irreplaceable items, and even exhibition cases for museum display and storage rooms.

Whilst protecting assets is not a requirement in fire regulations, the last few years have seen major fires to museums and stately homes, resulting seen the loss of priceless, irreplaceable items; like this fire at the National History Museum in Delhi, and this fire at Clandon House.

When considering fire-resistant glass, there are three main classifications:

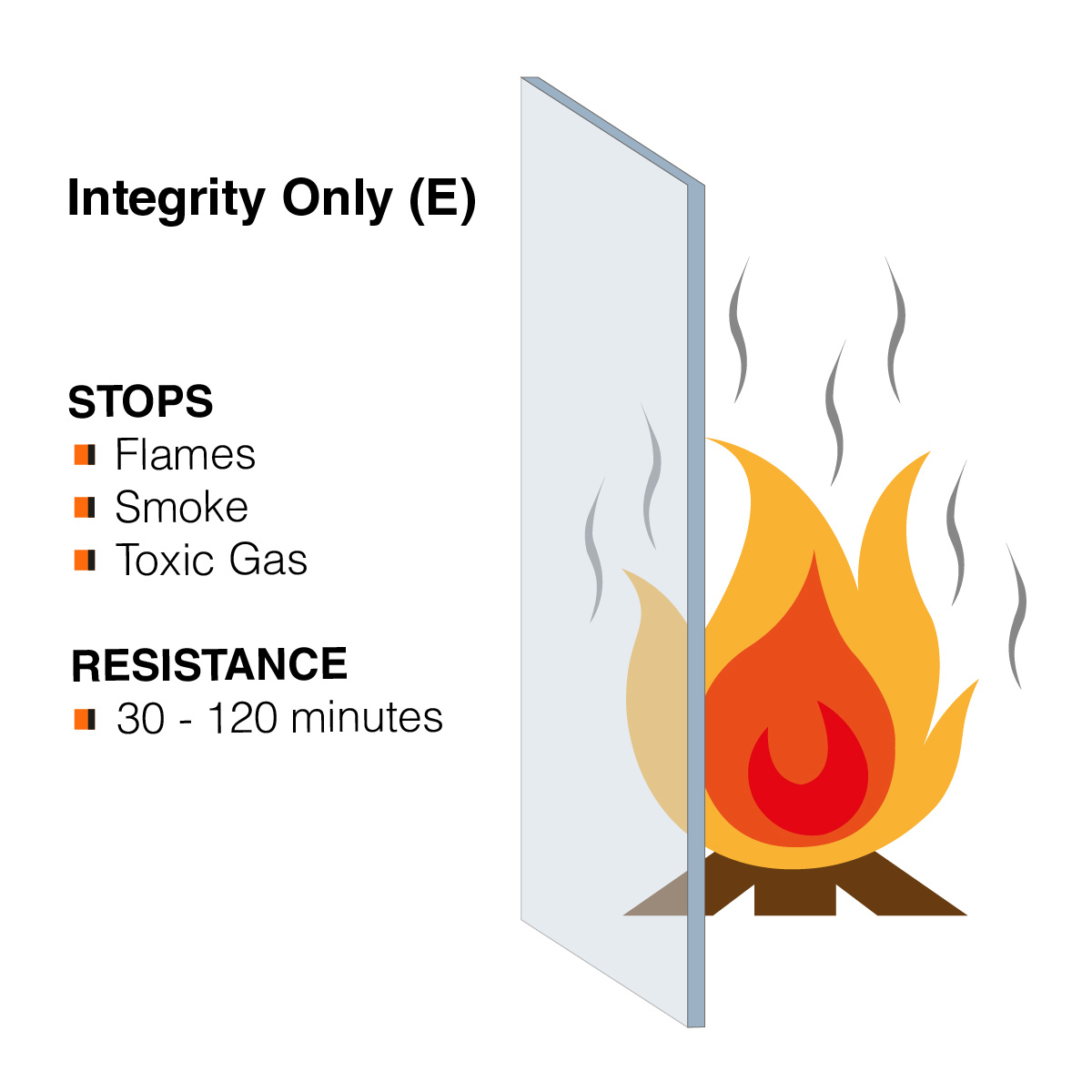

Integrity Only (E)

Integrity is your first line of defence, it stops flames, smoke and toxic gases. Available from 30 -120 minutes of protection. It does not stop heat transmission.

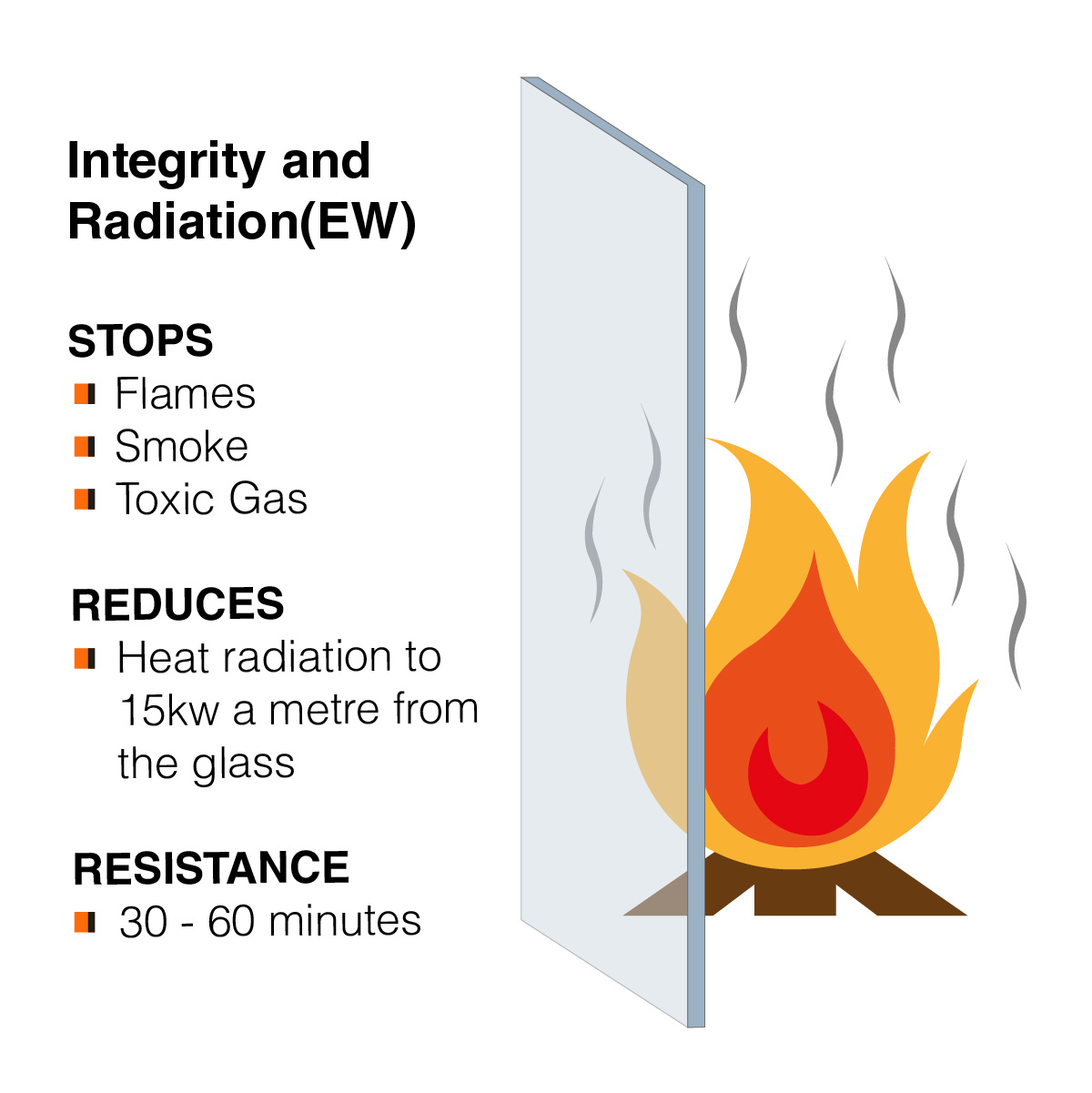

Integrity and Radiation (EW)

Integrity and radiation protection from flames, smoke, toxic gases and provides a barrier to radiated heat. This means that on the safe side of the glass, heat transference remains below 15 kW a square metre in front of the glass, which is enough to prevent objects from combusting on the safe side of the glass. Available for 30-60 minutes of protection.

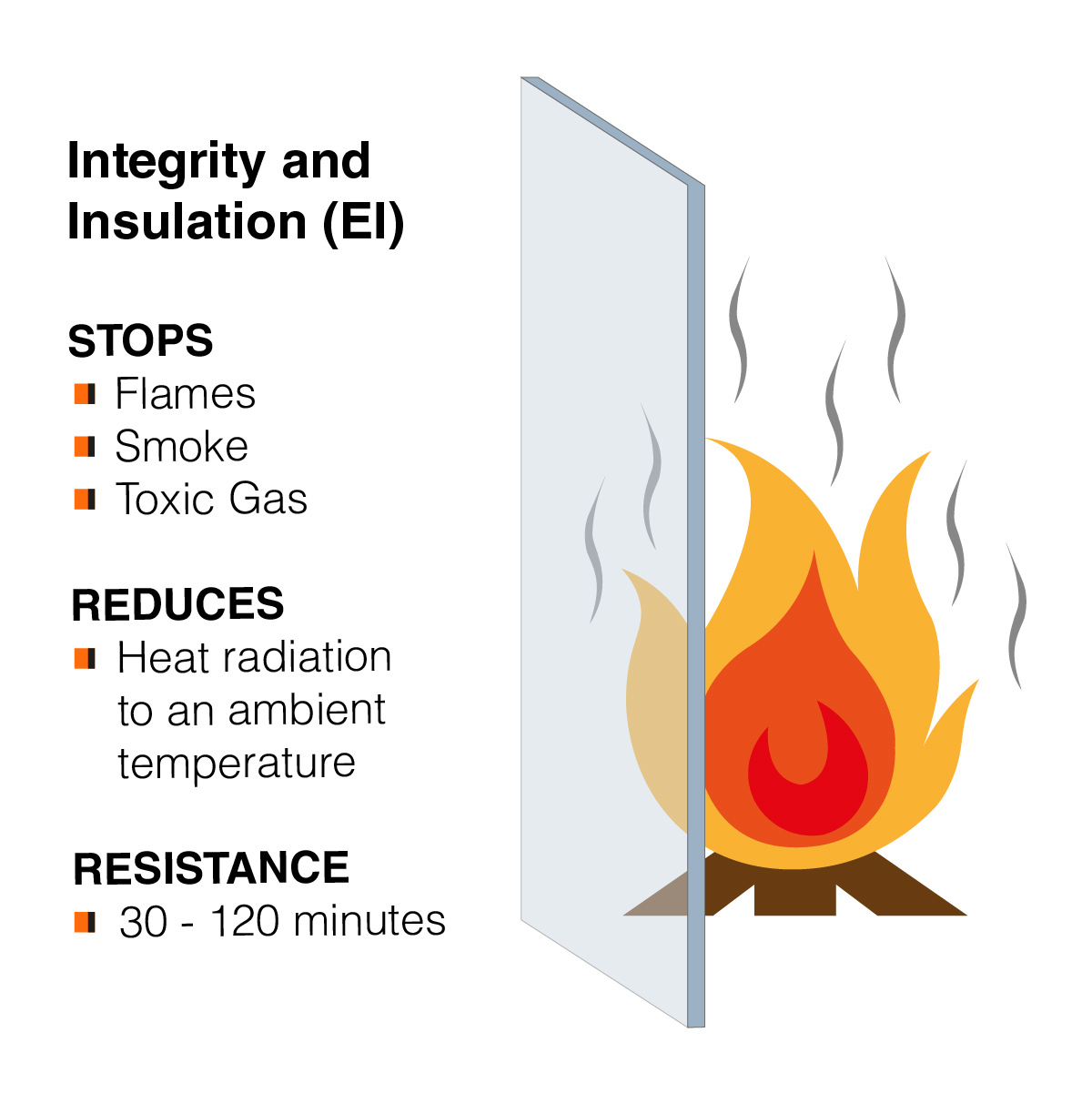

Integrity and Insulation (EI)

Integrity and Insulation is the highest performing FR glazing product on the market. It protects against flames, smoke, and toxic gases, and reduces heat on the safe side of the glass to an ambient temperature. The heat reduction also prevents objects from combusting on the safe side of the glass and is available with 30 – 120 minutes of protection.

Your fire officer will advise on the fire-resistant glass and fire-resistant frame that will meet fire regulations. Dellner Glass have the expertise and know-how to advise further on the best fire-resistant glass that will meet the overall needs of the construction, including optional aesthetic extras such as solar control, low E, and even security requirements such as bullet and physical attack resistance.

All fire-resistant glass supplied by Dellner Glass is tested to BS EN 1634-1:2008 and BS 476-22:1987. Dellner Glass’s manufacturing processes are fully certified to ISO9001 and hold both ISO 14001, ISO 18001, together with all relevant individual international product certifications.

To find out more, contact our sales team.

.jpg)